How To Install Vinyl Windows With Nail Flange

one / 26

Dorsum in the day, about window installations went something similar this: Gear up, level, square, nail, spray cream, rinse, repeat. But at that place are a few more than steps these days, and not all of them take to do with preventing water from getting within. In fact, many modernistic window installation steps are designed to allow water out, if it e'er does find a manner in.

To make sure nosotros got it right, nosotros asked our local Tyvek rep Lori Gunderson and Marvin Window installation guru Eric Klein to walk u.s. through the process. In add-on to proper procedures, Eric shared a bunch of installation pro tips, hints, and tricks.

In this story we demonstrate how to install a Marvin double hung window. Many of these steps are common among window manufacturers, but not all of them. When installing a window, ever follow the specific pedagogy intended for the brand you are working with.

two / 26

Cut Out the Opening

- Roll the house wrap, or WRB (Weather Resistant Bulwark), over the entire window opening.

- And then slice down the center of the WRB and cut it flush at the top and bottom of the opening.

3 / 26

Angle-Cut the Corners

- Cutting at an bending about six-in. up and away from all four corners.

- Annotation: The bottom angle cuts are not required by all window manufacturers.

four / 26

Fold Back the Flaps

- Fold dorsum the side-flaps and hold them in place temporarily with seam seal or house wrap tape, not staples.

- Pro Tip: Utilize a small piece of tape and so it doesn't tear the WRB when it's removed.

- Patch any tears that do occur with seam seal record. If at that place are no fasteners in the way, fold the WRB dorsum nether itself.

5 / 26

Slope the Sill With Siding

Fifty-fifty with a perfect install, water tin can still discover its way into the opening. Information technology'south a good idea to slope the sill in the rough opening to help unwanted h2o find its manner out again. Accomplish the slope by ripping down and installing a beveled slice of weather resistant siding.

- Plan ahead and build the rough openings virtually one/2-in. taller to account for the width of the siding.

- Shim under the siding if the opening is super out of level, only avoid raising the window higher than other windows nearby. The deviation in height will be noticeable and unsightly.

6 / 26

Install the Sill Pan Flashing

Nosotros're installing Dupont FlexWrap on this window. There are other acceptable products on the market place, but FlexWrap has a great track record and is recommended by the folks at Marvin.

- Tear the 6-in. backing off the flashing tape and lay the tape downwards over the sill flush with the interior framing.

- Run the tape a minimum of six inches upwards the sides of the opening.

- Pro Tip: Eric pushes the tape tight into the corners with a speed or rafter square.

seven / 26

Roll Out the Flashing

- Remove the smaller strip of backing and push the tape down onto the wall. This flashing is pressure sensitive and needs to be pressed in identify with a roller.

-

- Pro Tip: On super common cold days the stretched corners of the FlexWrap tin whorl back just a bit. Hold them down in place with a strip of seam seal tape.

-

eight / 26

Install Shims on the Sill

-

- Set the lower shims (preferably composite) in place before setting the window.

- Pro Tip: Eric dabs a trivial sealant under the shims. That helps keep them in place when setting the window merely keeps them loose enough, so they can exist moved for small-scale adjustments later.

- Space the shims nearly the edges, in the center, and for larger windows ane no more than xiv-in. apart.

- Set the lower shims (preferably composite) in place before setting the window.

nine / 26

Fold in Sides

- Wrap the two side WRB flaps within, around, and on to the inside framing.

- Staple or tape it in place.

10 / 26

Seal the Sides and Superlative Before Setting the Window

-

- Run a 3/8-in. bead of sealant about one-half inch in from the edge of the opening.

- Leave a 3/4-in. gap on each side of all four corners. Leaving the corners costless of caulk ensures the corner gaskets have a clean, smooth surface to adhere to.

- Don't caulk under the bottom nailing flange. Almost outside form "Window, Door, and Siding" sealant will work.

eleven / 26

Align the Inside of the Window

There is no reason to plumb the window considering if the wall is out of plumb, so goes the window. Only do the trim carpenters a favor and double check that the window jambs are as even with the framing as possible. If 1 side of the window protrudes in further than another, installing casing can be a difficult proposition. Only make small adjustments. Over-twisting the window could cause the sashes to jam or stick instead of operating smoothly.

12 / 26

Level and Spike the Bottom

- Have a helper on the within center the window in the opening.

- Adjust the shims and then that the bottom of the window is level so that each i is in contact with the window.

- Install two 2-in. exterior grade fasteners on each side near the lesser of the window, and so bank check the bottom again with a level.

- Pro Tip: Eric prefers screws to nails considering it's easier to readjust the window if something gets out of whack. GRK cabinet screws are his favorite.

xiii / 26

Square and Fasten the Superlative

- Check that the window is square past measuring diagonally both ways.

- Conform the pinnacle of the window one way or the other until the measurements are the same.

- Pro Tip: To ensure an accurate measurement, always hooks the record nether the vinyl drip cap. The baste cap too helps hold his tape measure out in place.

- Install two fasteners at the top about the corner, and then cheque for square again.

- Don't install any more than fasteners until the window is shimmed and sealed on the inside.

14 / 26

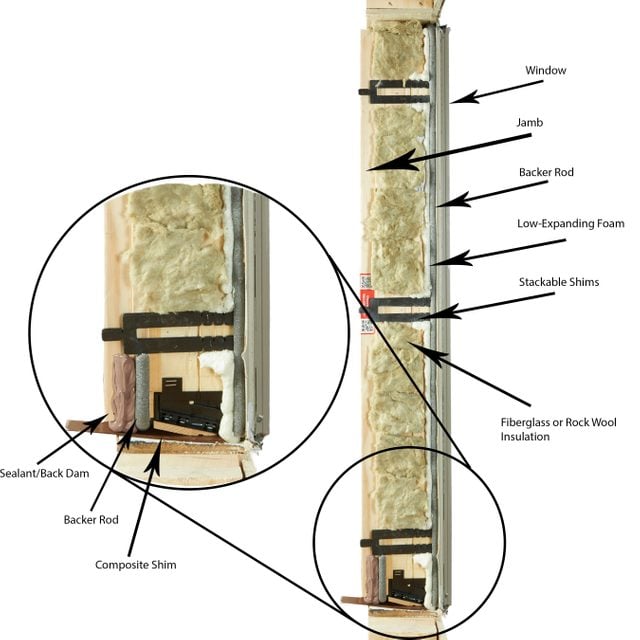

Seal up the Inside

This side by side section will walk you through the process of sealing around the window. Pictured in a higher place is what information technology should look like when you are all washed. Note: Once again, this is an canonical method for installing Marvin windows. Other manufacturer'southward methods will vary.

15 / 26

Install Backer Rod on the Sides and Elevation

-

- Before installing whatsoever more shims insert a capitalist rod on both sides and the superlative, but not the lesser.

- Push the capitalist rod tight upwards against the dorsum of the nailing flange.

- Pro Tip: Eric uses his speed/rafter square to make several passes pushing in only a couple inches at a time.

- The thought behind this capitalist rod is to eliminate thermal bridging and h2o infiltration. It prevents the side shims from butting up confronting the nailing flange, which could channel heat and water.

xvi / 26

Straighten the Jambs

There are iii means to bank check that the jambs are straight before installing the side shims:

- Inspect the reveals (space) between the jambs and the sashes. They should exist fifty-fifty.

- The distance between the two side jambs should be equal at the top, center, and bottom. This tin can be checked simply by measuring. PRO TIP: Instead of measuring, Eric uses the top stop as a story pole and compares the gaps between the stop and the jamb at the pinnacle, lesser, and center. Create your own story pole if the window you're installing does not have a top stop, and you take a bunch of them to install.

- Open and close both sashes to ensure they operate smoothly.

17 / 26

Install the Side Shims

- Install shims on the sides of the window in the center, and near 4 inches downwards from the peak and up from the bottom.

- Some windows accept defended holes to spike the jambs to the framing (meet next page). Place shims in those locations.

- Often, the center of the side jambs will have to be pushed in a bit.

- Pro Tip : Eric nudges the jambs over with an Air Shim pocketbook to the verbal position he wants, and then installs the shims.

- Don't shim the top of the window. If the building settles, the window could get compressed, which volition likely cause the window to stop working properly and could even result in broken panes of drinking glass.

18 / 26

Install the Inside Screws

In add-on to the fasteners in the nailing flange, this window is held in identify with screws run through a bracket called the receiver block. It'due south located in the checkrail and can exist accessed past removing the lower sash. The shims should exist located at these locations.

-

- Pro Tip: A long bid holder will make it easier to avoid scuffing the window with the drill chuck.

19 / 26

Cream the Sides and Top

- Run a bead of low-expanding foam in the gap along side the capitalist rod. Don't over practise it. Just dispense enough cream to create a ane or 1-one/two-in. dewdrop that bridges the unabridged gap between the window and the framing.

- Run the dewdrop out a little ways forth each side of the shim. Don't fill up the whole infinite in because fifty-fifty depression-expanding cream tin can expand plenty to misconstrue the jambs.

- Pro Tip: Lay out a practice bead on a piece of cardboard, so you can adjust the gun, and guess how fast to move the tip along inside the gap.

20 / 26

Install the Lesser Backer Rod

- Starting at one of the lower shims, button in a backer rod effectually the bottom and up to the other shim.

- Don't button information technology all the way in like you did with the other backer rod. Only push in nearly to the signal where the jamb meets the window unit.

21 / 26

Create a Back Dam

- Make full the gap from the lower backer rod almost all the way to the inside edge of the framing.

- Tool in the sealant with your finger or a small chunk of backer rod to ensure that the whole gap gets filled. This back dam will prevent any water that gets by the other lines of defense from getting inside the house.

- If the window is installed properly in that location should be nothing stopping the water from escaping dorsum to the great outdoors.

22 / 26

Add together Insulation

- Fill up in the rest of the gap on the sides (to a higher place the lower shims) and the pinnacle with fiberglass or rock wool insulation.

- Fill the whole gap, but go along it loose and fluffy. Insulation loses its effectiveness the more tightly packed it gets.

23 / 26

Add Corner Gaskets

- If the window yous're installing requires corner gaskets, now'south the fourth dimension to install them.

24 / 26

Tape the Flanges

Some windows take a nailing flange that is an integral part of the window (usually vinyl windows), only this window does not. And then in club to seal the area where the flange meets the window, the flashing tape needs to be stitch onto the side of the window at least one/iv-in.

- Install the record on the sides first, nigh iv inches past the bottom of the window and about an inch higher than the upper nailing flange.

- Run the flashing tape at the top at least six inches past the window on each side.

25 / 26

Record the Pinnacle Flap

- Fold downwardly the top flap of WRB and cover the ii angled cuts with seam seal tape.

- Don't tape the unabridged lesser of the flap. Instead, just apply a few small strips of tape to hold it in place. The gaps between the tape are there to create an escape route for whatsoever h2o that gets behind the WRB higher up the window opening.

26 / 26

Washed!

That'south all in that location is also it! Okay, nosotros admit that window installation is not as simple and easy equally used to be…just neither are water damage and callbacks. We desire to thank our two experts for stopping past and walking united states through the entire process:

Meet the experts

Lori Gunderson

Lori has been a Tyvek Specialist for over 12 years. She works closely with Architects, General Contractors, Builders, and installers to help build a quality, energy efficient building. Before becoming a Tyvek Specialist, she worked for a national builder for over ten years where she managed single family and multifamily projects.

Eric Klein, Senior Installation and Service Instructor

Eric has been employed by Marvin Windows and Doors since March of 1984 and has trained thousands of installers in the facilities at Warroad, MN and on his travels that accept taken him across the earth. He is an Accredited Instructor and certifies installers in the Residential, Light Commercial, and Commercial window and door installation. Eric likewise works with several associates and vendors on how to improve serve the installers, contractors, and service techs with improve tips and tricks, and installation knowhow.

More than resource:

http://www.dupont.com/products-and-services/fabrics-fibers-nonwovens/protective-fabrics/brands/tyvek.html

https://world wide web.marvin.com/

Source: https://www.familyhandyman.com/list/window-installation-the-right-way/

Posted by: brucethund1989.blogspot.com

0 Response to "How To Install Vinyl Windows With Nail Flange"

Post a Comment